Automotive spray booths are essential for vehicle refinishing and manufacturing, providing a controlled environment that ensures high-quality paint application. These enclosed spaces regulate airflow, temperature, and humidity, preventing dust contamination and ensuring a smooth, even finish.

Compliance with industry standards is crucial for both safety and efficiency. Regulations govern ventilation, fire safety, and environmental impact, ensuring that operations meet legal and health requirements. Non-compliance can result in fines, operational shutdowns, or safety hazards, making it vital for businesses to follow best practices. Understanding these requirements helps operators maintain a safe workplace while achieving professional-quality results.

Understanding Automotive Spray Booths

Definition and Purpose

Automotive spray booths are enclosed spaces designed to provide a controlled environment for painting vehicles. They regulate temperature, humidity, and airflow to ensure even paint application while preventing dust, debris, and contaminants from affecting the finish. These booths also improve workplace safety by containing hazardous fumes and overspray, reducing exposure to harmful chemicals.

In professional body shops and manufacturing facilities, spray booths are essential for meeting industry standards. They help ensure consistent quality, protect workers from toxic vapours, and reduce environmental impact by controlling emissions and waste.

Types of Spray Booths

Crossdraft Booths

Crossdraft spray booths draw air from one end of the booth and exhaust it out the opposite end. This simple design is cost-effective and requires minimal installation space, making it popular for smaller operations. However, because air moves horizontally across the vehicle, there is a higher chance of dust or overspray affecting the finish.

Downdraft Booths

Downdraft booths pull air from the ceiling and exhaust it through vents in the floor. This vertical airflow minimises contamination by directing overspray away from the vehicle’s surface, ensuring a cleaner, high-quality finish. These booths are commonly used in high-end automotive refinishing and manufacturing due to their superior air management.

Side Downdraft Booths

Side downdraft booths function similarly to downdraft systems but exhaust air through side-mounted filters instead of the floor. This setup is a practical alternative when floor exhaust systems are not feasible, offering improved airflow control compared to crossdraft booths while being more affordable than full downdraft models.

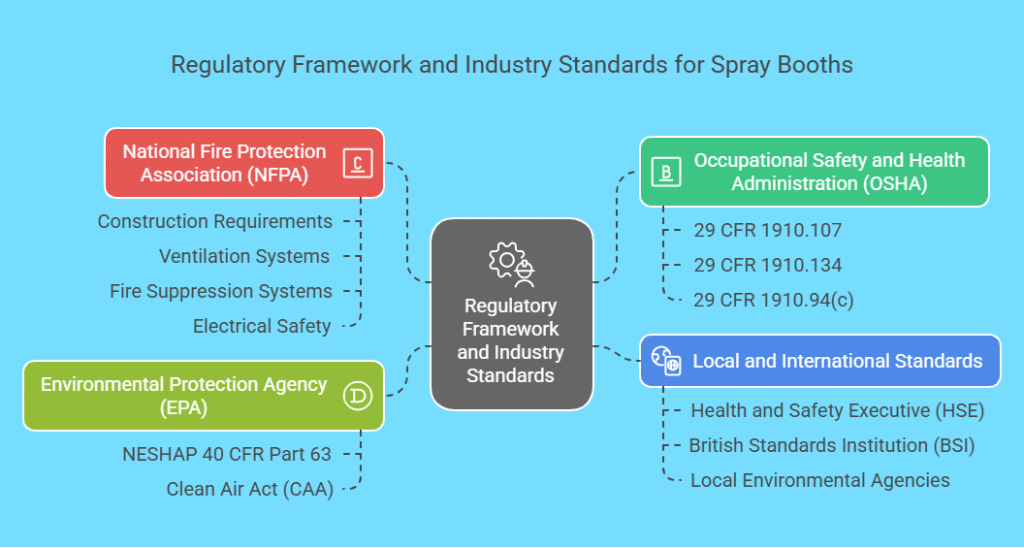

Regulatory Framework and Industry Standards

Ensuring compliance with regulatory standards is crucial for the safe and efficient operation of automotive spray booths. Regulations cover worker safety, fire prevention, and environmental impact, helping businesses avoid penalties and maintain best practices.

Occupational Safety and Health Administration (OSHA)

In the United States, the Occupational Safety and Health Administration (OSHA) enforces workplace safety regulations, including those related to spray booths. While OSHA regulations do not apply directly in the UK, similar health and safety principles are enforced by the Health and Safety Executive (HSE).

Key OSHA regulations include:

- 29 CFR 1910.107 – Specifies fire safety requirements, including ventilation, fire suppression systems, and electrical safety within spray booths.

- 29 CFR 1910.134 – Covers respiratory protection for workers exposed to hazardous fumes and vapours.

- 29 CFR 1910.94(c) – Mandates proper ventilation in spray finishing operations to prevent airborne contaminants from reaching dangerous levels.

UK businesses can use OSHA guidelines as a reference while ensuring compliance with HSE Control of Substances Hazardous to Health (COSHH) and Dangerous Substances and Explosive Atmospheres Regulations (DSEAR), which outline similar safety measures.

Read More: See Masterflo spray booths in action around the UK

National Fire Protection Association (NFPA)

The National Fire Protection Association (NFPA) provides fire safety guidelines for spray booths through NFPA 33: Standard for Spray Application Using Flammable or Combustible Materials. This standard focuses on reducing fire hazards associated with paint spraying operations.

Key aspects of NFPA 33 relevant to spray booths include:

- Construction Requirements – Spray booths must be built using non-combustible materials and be properly grounded to prevent static discharge.

- Ventilation Systems – Exhaust airflow must meet minimum velocity requirements to safely remove flammable vapours.

- Fire Suppression Systems – Automatic fire suppression, such as sprinklers or dry chemical systems, is required for compliance.

- Electrical Safety – All electrical components within the booth must be explosion-proof to prevent ignition of flammable fumes.

While NFPA standards are primarily followed in the US, UK businesses must adhere to British Standard BS 7671, which governs electrical safety in hazardous environments, and HSE HSG178, which provides guidance on fire risks in vehicle paint spraying.

Environmental Protection Agency (EPA)

The Environmental Protection Agency (EPA) regulates emissions from spray booths to minimise air pollution and protect public health. Key EPA regulations include:

- National Emission Standards for Hazardous Air Pollutants (NESHAP) 40 CFR Part 63 – Limits volatile organic compound (VOC) emissions from spray finishing operations.

- Clean Air Act (CAA) – Enforces emission controls and requires businesses to use approved filtration systems to reduce pollution.

In the UK, similar environmental regulations fall under the Environmental Protection Act 1990 and The Environmental Permitting (England and Wales) Regulations 2016, which mandate businesses to control emissions from industrial processes. Compliance often involves using high-efficiency particulate air (HEPA) filters and low-VOC paint formulations.

Local and International Standards

Regulations for spray booths vary by region, and businesses must comply with local laws in addition to international best practices. In the UK, key authorities include:

- Health and Safety Executive (HSE) – Enforces workplace safety, including COSHH and DSEAR regulations for hazardous substances.

- British Standards Institution (BSI) – Publishes standards such as BS EN 16985:2018, which outlines safety requirements for spray booths.

- Local Environmental Agencies – Require permits for spray operations that produce emissions above a certain threshold.

Failure to comply with local standards can lead to fines, legal action, or operational shutdowns. Businesses must regularly review their compliance status and invest in equipment that meets or exceeds the latest regulatory requirements.

Read More: Portable Retractable Spray Booths

Key Compliance Requirements

Ensuring compliance with industry regulations is essential for the safe operation of automotive spray booths. Proper design, ventilation, electrical safety, fire protection, and operational practices all contribute to a safe working environment and high-quality paint finishes.

Design and Construction

Materials

Spray booths must be constructed using non-combustible materials such as galvanised steel or aluminium to prevent fire hazards. Walls, ceilings, and floors should be resistant to solvents and paint overspray to ensure durability and easy maintenance. Any insulation used should also be fire-resistant and compliant with British Standard BS EN 13501-1, which classifies materials based on their fire resistance.

Dimensions and Layout

Adequate space is required for safe operations and routine maintenance. Booths should be large enough to accommodate vehicles while allowing unrestricted movement for workers. The layout should ensure a minimum clearance between the vehicle and booth walls to facilitate airflow and prevent paint contamination.

Access and Egress

Emergency exits must be clearly marked and unobstructed, with doors designed to open outward in case of an emergency. The Health and Safety Executive (HSE) Workplace (Health, Safety and Welfare) Regulations 1992 specify that exits must be placed at strategic locations to allow quick evacuation. Doors should also be fire-rated to prevent the spread of flames and fumes in case of ignition.

Ventilation and Airflow

Air Velocity

Maintaining the correct air velocity is crucial to preventing the accumulation of flammable vapours. The recommended airflow rate for spray booths, as per HSE guidelines, is 0.3 to 0.5 metres per second across the worker’s breathing zone to effectively remove hazardous substances.

Exhaust Systems

Exhaust systems must be designed to safely extract contaminated air while meeting Environmental Protection Act 1990 regulations. Ductwork should be made of non-combustible materials, have minimal bends to reduce airflow resistance, and be positioned to prevent recirculation of contaminated air. High-efficiency particulate air (HEPA) filters or activated carbon filters may be required to capture fine particles and volatile organic compounds (VOCs).

Makeup Air

To balance the removal of air, makeup air systems must introduce clean air at a controlled rate. This prevents negative pressure inside the booth, which can disrupt airflow and cause contamination. Temperature-controlled makeup air units ensure a stable working environment, particularly in cold weather, improving paint application consistency.

Electrical Safety

Equipment Classification

All electrical components within the booth must comply with BS EN 60079, which governs explosion-proof electrical equipment in hazardous areas. Lighting fixtures, wiring, and switches should be sealed to prevent ignition of flammable vapours.

Static Electricity

Paint spraying generates static electricity, which can ignite flammable solvents if not properly controlled. Booths should be grounded and bonded, ensuring all metal parts are electrically connected to a common ground point. Workers should use anti-static footwear and grounding straps to further minimise risks.

Fire Protection

Suppression Systems

Spray booths must be equipped with automatic fire suppression systems, such as:

- Water-based sprinklers, compliant with BS EN 12845, which automatically activate in case of a fire.

- Dry chemical or CO₂ systems, which suppress fires without damaging equipment.

- Foam-based systems, useful for applications involving highly flammable coatings.

Fire Extinguishers

Portable fire extinguishers should be placed near the booth entrance and in easily accessible locations. The recommended extinguisher types include:

- CO₂ extinguishers for electrical fires.

- Foam extinguishers for flammable liquids.

- Powder extinguishers for mixed fire risks.

The Regulatory Reform (Fire Safety) Order 2005 mandates regular fire risk assessments to ensure adequate protection measures are in place.

Operational Practices

Training

All personnel working in spray booths should undergo mandatory safety training, covering:

- Safe handling of paints and solvents

- Proper use of PPE

- Emergency procedures and fire safety

Training should be regularly updated to reflect changes in HSE guidance and best practices.

Maintenance

Routine inspection and maintenance of spray booths are essential to prevent malfunctions and ensure ongoing compliance. This includes:

- Cleaning air filters to maintain airflow efficiency.

- Checking ventilation ducts for blockages.

- Inspecting fire suppression systems to ensure they are operational.

Maintenance schedules should be documented and aligned with manufacturer recommendations and regulatory standards.

Personal Protective Equipment (PPE)

Workers must wear appropriate PPE to minimise exposure to hazardous substances. This includes:

- Respiratory protection, such as air-fed masks meeting BS EN 12941 standards.

- Protective overalls resistant to chemical exposure.

- Gloves and safety goggles to protect skin and eyes from paint and solvent splashes.

Read More: Masterflo Spray Booths – An Overview

Common Compliance Challenges and Solutions

Despite the clear benefits of adhering to industry regulations, many businesses struggle with compliance due to technical, financial, and operational constraints. Identifying these challenges and implementing proactive solutions can help businesses maintain a safe and legally compliant working environment.

Challenge: Maintaining Consistent Airflow Rates

Proper airflow is essential in automotive spray booths to prevent the build-up of flammable vapours and overspray contaminants. However, maintaining the correct air velocity can be difficult due to clogged filters, worn-out fans, or changes in booth usage patterns.

Solution: Regular Testing and Calibration of Ventilation Systems

Businesses should establish a preventative maintenance programme that includes:

- Frequent air velocity testing using an anemometer to ensure compliance with HSE-recommended airflow rates (0.3–0.5 m/s at the breathing zone).

- Scheduled filter replacements to prevent airflow blockages.

- Routine inspection of exhaust fans and ductwork to detect and resolve any obstructions.

Adhering to manufacturer maintenance guidelines and regulatory requirements will help businesses maintain optimal airflow performance.

Challenge: Proper Disposal of Hazardous Waste

Automotive spray operations generate hazardous waste, including solvent-contaminated rags, leftover paint, and used filters, which must be disposed of safely to comply with Environmental Protection Act 1990 and The Hazardous Waste Regulations 2005.

Solution: Implementing Waste Management Protocols

To ensure compliance, businesses should:

- Use sealed waste containers for solvent and paint waste to prevent leaks and spills.

- Work with licensed hazardous waste disposal providers who can safely handle and dispose of toxic materials.

- Implement solvent recycling to reduce waste and operating costs.

Proper waste management not only ensures regulatory compliance but also reduces environmental impact.

Challenge: Keeping Up with Evolving Regulations

Regulatory requirements for spray booths frequently change as health, safety, and environmental standards evolve. Many businesses struggle to stay informed and risk non-compliance due to outdated practices.

Solution: Subscribing to Industry Bulletins and Engaging with Professional Organisations

Businesses can stay updated by:

- Subscribing to HSE, British Coatings Federation (BCF), and industry association newsletters for regulatory updates.

- Attending industry seminars and networking events to gain insights on best practices.

- Engaging compliance consultants for expert guidance on new regulations and implementation strategies.

By staying informed, businesses can proactively adjust their operations to meet new compliance standards, avoiding penalties and ensuring long-term success.

Read More: Modular Retractable Spray Booths

Final Thoughts

Ensuring compliance with automotive spray booth standards is crucial for safety, efficiency, and environmental responsibility. Key areas include airflow, fire prevention, waste disposal, and electrical safety. Non-compliance can result in legal penalties, fire risks, and poor air quality. Investing in compliant equipment, training, and maintenance helps mitigate these risks and boosts performance. Regular inspections and staying updated on regulations ensure safer environments, quality finishes, and sustainability. Businesses unsure of their compliance can consult experts for tailored solutions to meet evolving regulations.